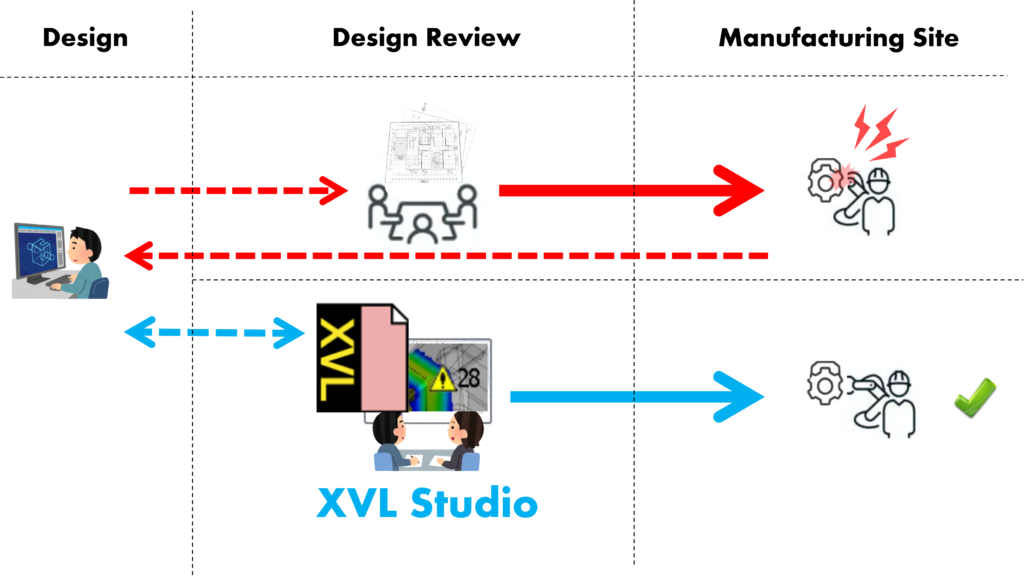

We’ve had frequent rework in assembly due to interference and procedure issues..

Have you looked into XVL Studio? It’s great for assembly validation.

* Reference (Previous blog article on XVL): ~ XVL Studio (Lattice) 1/2: Streamlining Design Reviews & Work Instructions ~

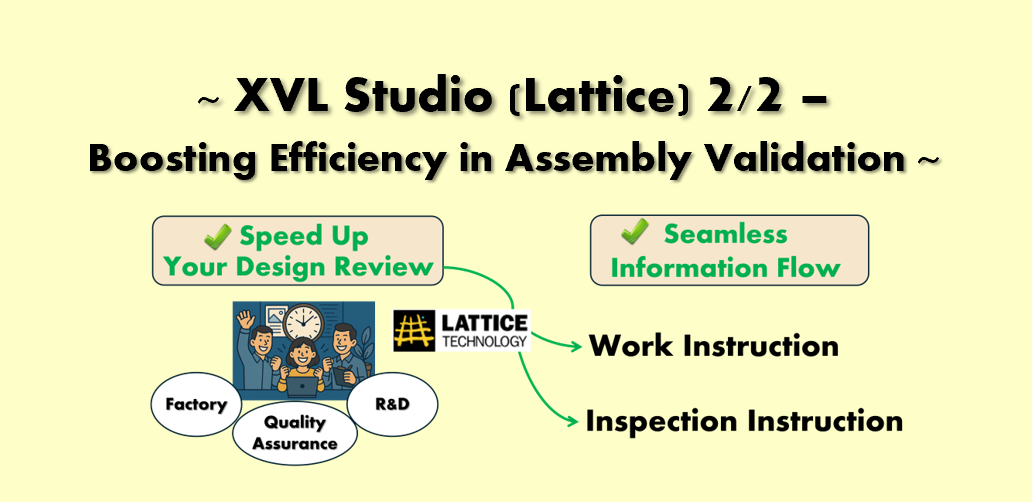

[Highlights of XVL Studio (Lattice): Efficient Assembly Validation]

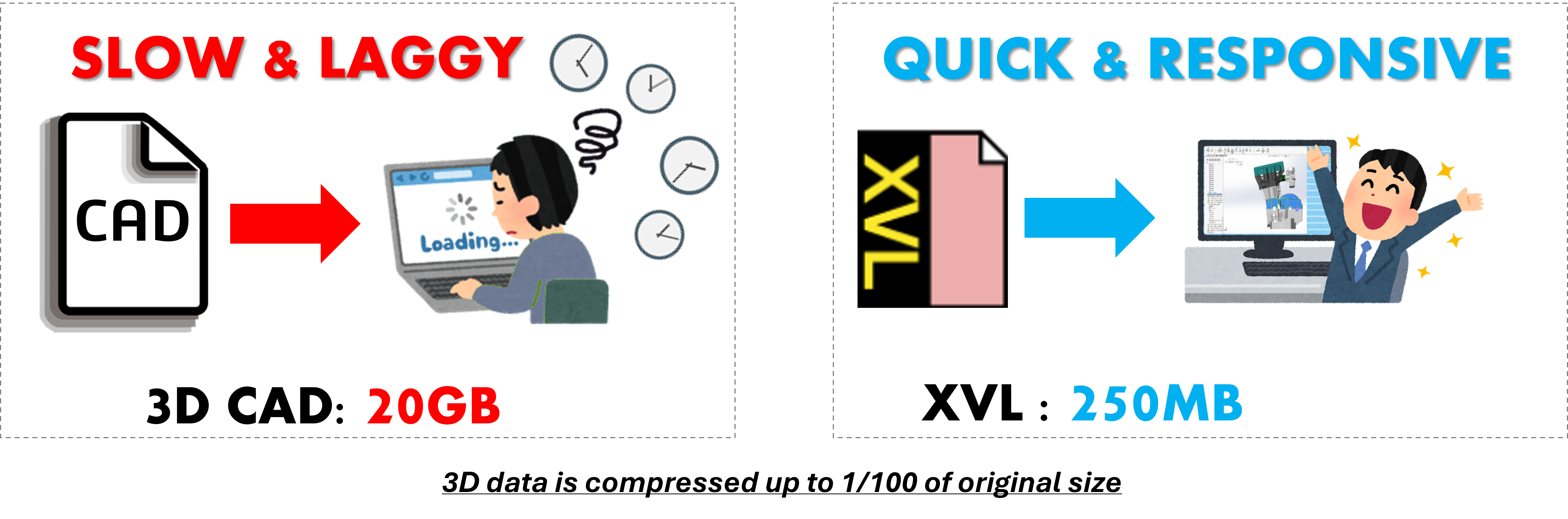

✓ Ultra-light 3D for smooth handling of large models, regardless of computer specs

✓ Verify interferences and work steps to catch assembly issues early

✓ Work simulations including visibility and accessibility checks

✓ Shared visuals align teams from design to quality, eliminating misunderstandings

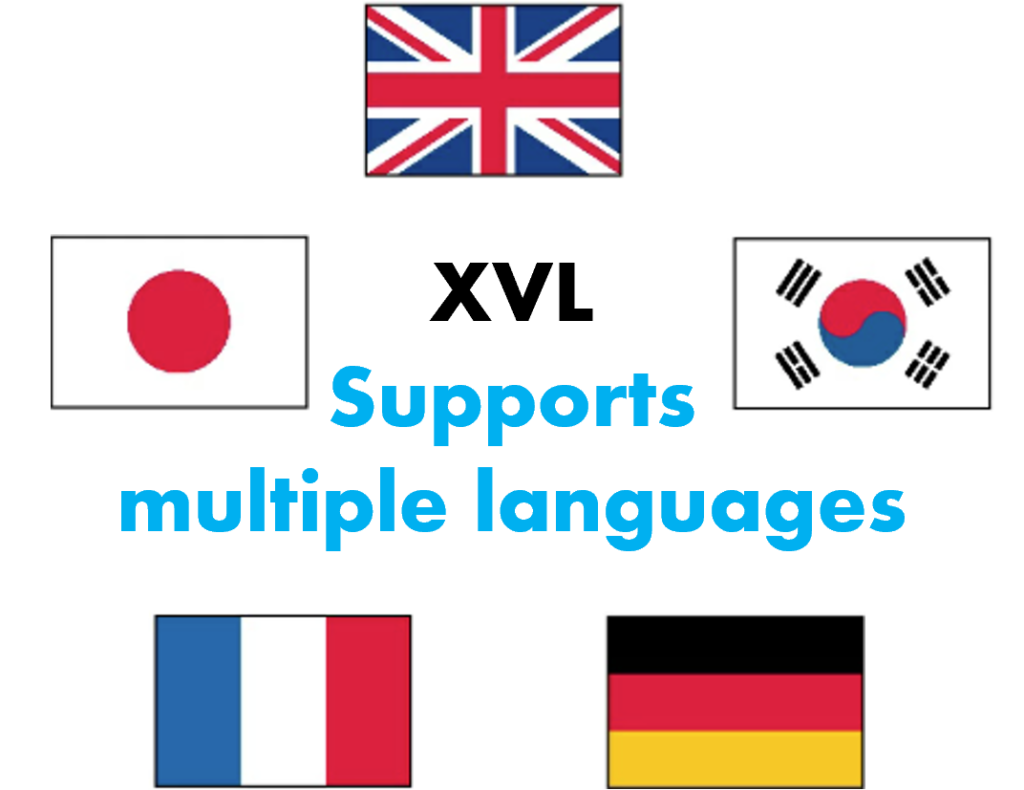

✓ Multilingual support and web sharing for seamless coordination with overseas locations

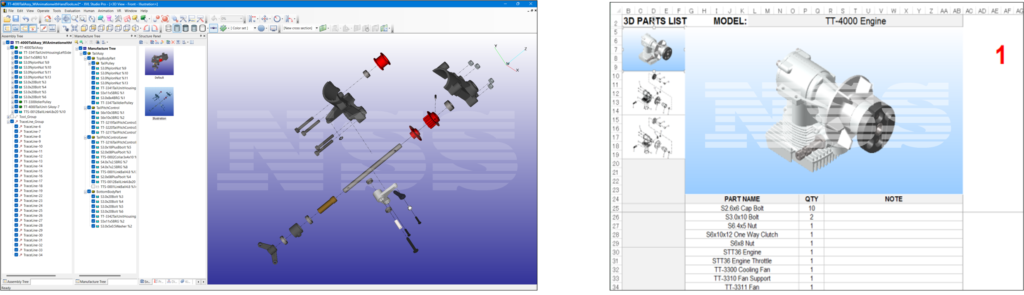

XVL imports the whole product as ultra-light 3D data, enabling step-by-step assembly simulations. It helps identify problems like interferences early on.

When opening CAD data, the files are so heavy that just loading the full model is a real struggle…

On that point, XVL is extremely lightweight. You can operate smoothly with large assemblies in XVL, regardless of your PC specs.

What level of detail can we check for the work procedures?

You can verify the assembly sequence and motion simulation at the component level , as well as check visibility and accessibility. It also allows inspection from the operator’s perspective.

I see… Isn’t the actual validation process quite complicated?

The interface is user-friendly, so anyone familiar with CAD can pick it up quickly. Plus, you can easily create slide-based reports of the validation results.

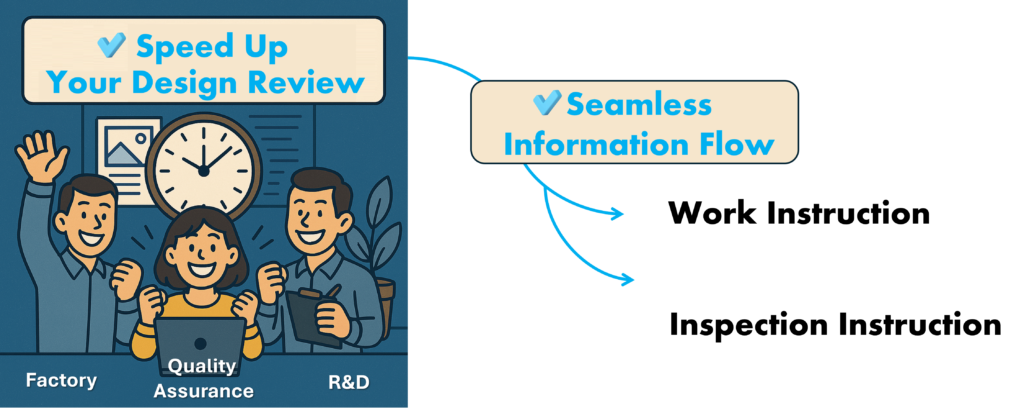

Right now, the main issue is that different departments—design, manufacturing, and quality assurance—aren’t on the same page.

Using XVL, the visualized 3D information becomes a common “language” across departments. This greatly reduces misunderstandings during reviews.

That would really help… We often face many conflicts among departments.

Many customers have shared great feedback that their design review time was drastically shortened after implementing XVL.

Also, it’s easy to integrate into work procedures and inspection instructions, ensuring smooth communication on the shop floor.

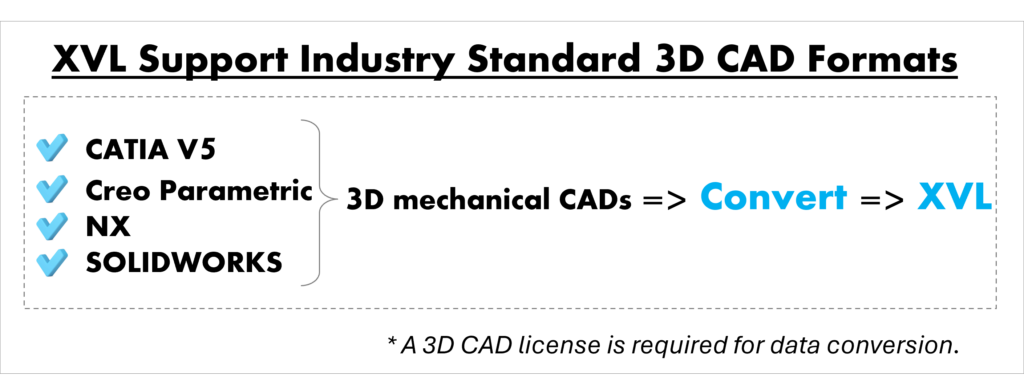

But doesn’t converting from CAD to XVL take a lot of effort?

The conversion process is automated and can be done with just one click.

It works with major CAD software like CATIA, and carries over part attributes and structure info, so data migration is hassle-free.

Good to hear it works well with CATIA, as that’s our primary CAD system.

Actually, any assembly errors are only found on the shop floor, not caught earlier…

Using XVL to check assembly during design greatly cuts down rework at the site. Recently, production engineering teams have started using it too, helping standardize processes and improve training efficiency.

Is it also easy to share the validation results with the shop floor?

Yes, you can share it through the web, so reviews and instructions can be coordinated smoothly even remotely.

Additionally, it supports multilingual display and uses animations and graphics to communicate intuitively, helping teams overcome language barriers.

With more collaboration happening with overseas locations lately, that’s definitely something we value. I’m now more interested in XVL!!