Hello!

In the previous blog, we already introduced the DELMIA Apriso. The solution for Manufacturing Operations Management (MOM) that helps customer’s factory to efficiently real-time controlling, tracking, and synchronizing manufacturing process.

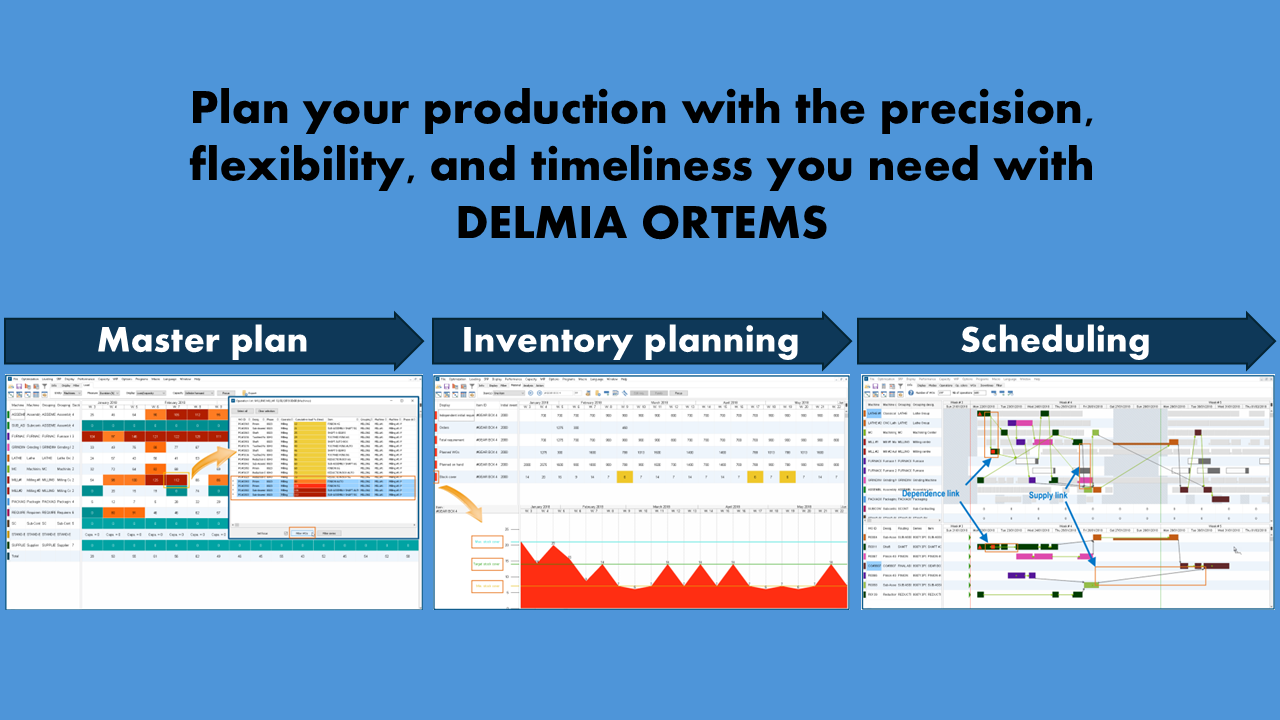

In this blog, we will introduce you the DELMIA ORTEMS

Sounds interesting!

So, what is the DELMIA ORTEMS?

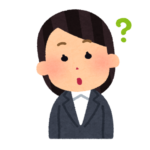

DELMIA ORTEMS is a solution in MOM which is a part of DELMIA offered by Dassault Systèmes.

✔ The DELMIA ORTEMS provides Advanced Planning & Scheduling (APS), Manufacturing Process Tracking, and Process Efficiency Improvement.

✔ The tool is creatively designed to help any factory to plan the production process by referring to process limitation. For example, Machine, Employee, Machine set-up, or Raw Material Availability. The real-time adjustable tool makes customers ready for any changes in production order. This helps manufacturers achieve their goal in Operational Excellence.

Great.

Recently we have been facing problems with production management and the improvement of planning efficiency.

We deeply understand.

No matter how good we manage in the working field. The “capability to deliver product to customer” and “Production Capacity” can still be impacted by two key factors

1. A Production plan that does not align with the process limitation

2. A Production plan that lacks flexibility for adjustments

Please provide us with more details about the issue you are facing so that we may assist you more thoroughly.

Of course, Our challenges are the unpredictable problems in production line. Sometimes we have already planned, but the customer rushes us or raw material delivery delays. We must re-manage all plan, or we have to do the OT almost every day. The unpredictable in production line and supply chain are inevitable. All these factors significantly impact the process efficiency.

We can categorize the challenges as follows:

Main Challenges:

- Inefficient production planning

The existing planning system lacks the efficiency to accommodate the growing complexity of the expanding production lines, leading to constraints in resource allocation and production process management. - Inefficient use of Resources

The machine and staff in factory is not being used with full potential, this makes loss of opportunities in increasing product and unnecessary higher of production cost. - The delay in product delivery

The inconsistency and delay in production process affects the delivery schedule. This makes customers unsatisfied and lower the monthly income of our company. - Lack of real-time information to track production process

Restriction to access real-time progress information of production process. This delays the business decision and lack of efficiency. This also cannot promptly respond to the change of situation.

Understand.

DELMIA ORTEMS is the appropriate solution for your needs.

DELMIA ORTEMS will solve all these problems by..

- Inefficient production planning

ORTEMS leverages advanced production planning technology (Advanced Scheduling Algorithms) that considers constraints such as machinery, manpower, and raw materials to generate the most optimized production plan. This empowers customers to manage the complexity of their production processes, reduce hard-to-solve issues and delays, and utilize resources more efficiently. As a result, production lead times are shortened, and products can be delivered more accurately and faster. - Inefficient use of Resources

With real-time resources tracking, ORTEMS can instant analyze and adjust resources. There will be no more inefficient use of machines and staff. Lower the production cost and increase product in production line. - The delay in product delivery

ORTEMS supports dynamic rescheduling to instantly adapt to changes in the production environment. This capability helps prevent revenue loss caused by delayed deliveries and enhances customer satisfaction by ensuring a more responsive and reliable production process. - Lack of real-time information to track production process

ORTEMS displays production data through real-time dashboards and analytics, enabling efficient management and operations. This allows users to make faster and more accurate decisions based on up-to-date information.

It is interesting as far as I’m concerned, especially the dynamic schedule and real-time information observation. This solution would help us to get planning more accurate and flexible.

This will undoubtedly contribute to a more positive work environment.

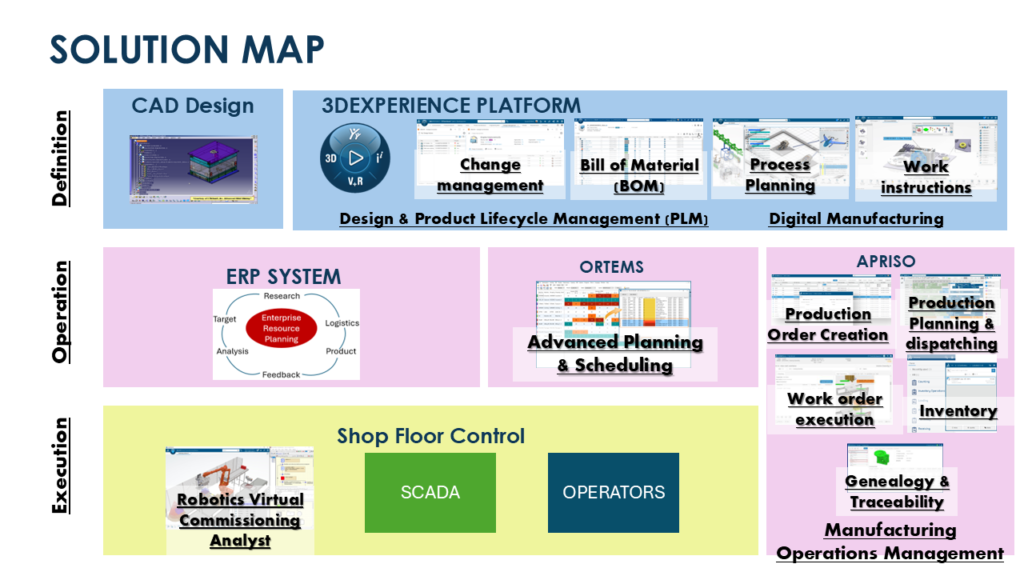

Yes! DELMIA ORTEMS also seamlessly connect to MES system from DELMIA Apriso. And when they are together, it will combine the capabilities of Production (from Apriso) and the most suitable Production Plan.

This fasten and accurate the decision from Planning Department to Production site staffs.

Did you mean that if we already have Apriso, we could extend it with ORTEMS to better in planning and effectively operate, right?

Correct, with the use of DELMIA ORTEMS together with Apriso, they elevate the overall production process management by connecting the precise planning with systematically and efficiently operation.

gdfgg

sffh

kgllllll

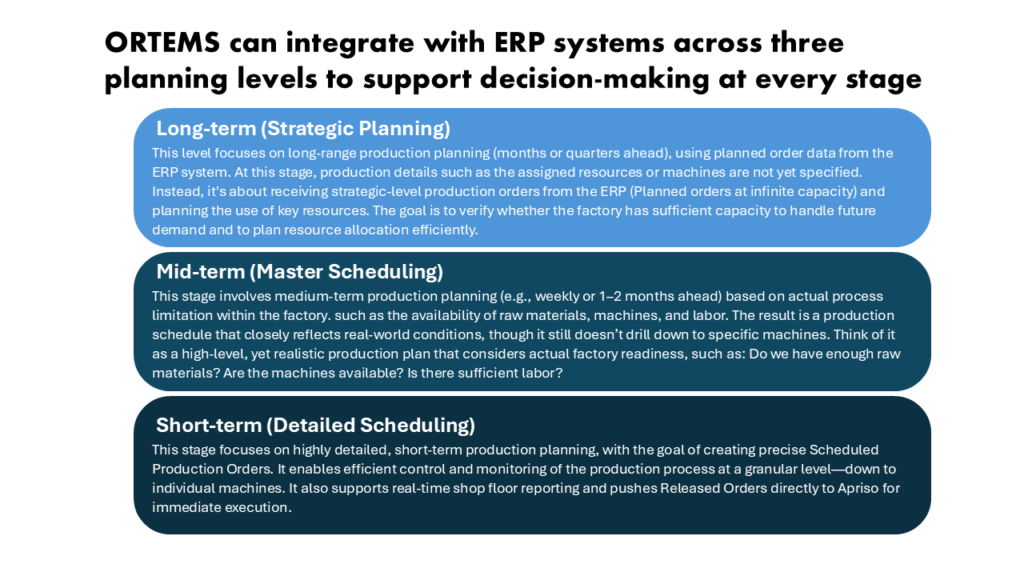

| Key Features | |

| Long-term (Strategic Planning) | 1.Ability to plan months or quarters in advance 2.Forecasting sales or order volume to assess whether the factory can meet future demand 3.Analyzing production capacity to accommodate upcoming orders 4.Supporting decisions to adjust production capacity, such as hiring or reducing the workforce 5.Viewing an overview of multiple factory sites in a single consolidated view |

| Mid-term (Master Scheduling) | 1.Takes real capacity into account, such as the actual available machine hours 2.Utilizes inventory data—including raw materials, work-in-progress (WIP), finished goods, lead times, and the Bill of Materials (BOM)—for accurate planning 3.Enables adjustment of production plans based on the current availability of materials 4.Supports management and prioritization of pending or backlogged orders, helping ensure a smooth production and delivery process 5.Allows for flexible plan adjustments in response to changing forecasts |

| Short-term (Detailed Scheduling) | 1.Ability to generate Gantt charts for detailed production scheduling, allowing planners to define specific activities such as production order setup, machine usage, resource allocation, and tracking the status of each production phase. 2.Real-time schedule adjustments. The production schedule can be modified in real time to respond to unexpected events such as machine breakdowns or quality issues with raw materials 3.Integration with MES (Manufacturing Execution System) Can connect seamlessly with shop floor control systems like DELMIA Apriso 4.Planners can simulate multiple scheduling scenarios without affecting the actual production plan(Scenario simulation), allowing them to compare options and make informed decisions during uncertainty or urgent changes 5.Controlled order release – Additional production orders can be released to the MES or shop floor only when resources are confirmed to be available (e.g., machines are idle, materials are ready, no order conflicts). This helps reduce production delays and accelerates time-to-market. |

In case you are interested, our team can provide you with deeper information, create Workshop, and demonstrate the System. This will allow your team to gain a clear understanding of the actual workflow and effectively evaluate the capabilities of the solution.

Thank you for the excellent explanation that makes us see a clearer picture of DELMIA ORTEMS.

We would like to have an internal discussion about this then we will consider the potential approaches for implementing the solution within our production processes in the next steps.

You’re welcome!

We’re here to walk with you through every stage of your transformation together.