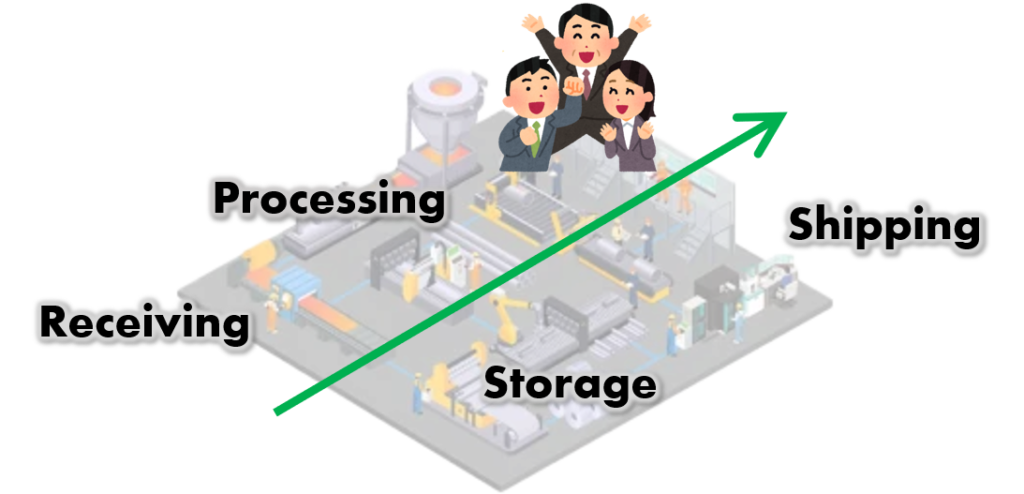

We are an automotive parts supplier and have been using an ERP (Enterprise Resource Planning) system for many years to manage our entire resource planning process. Thanks to ERP, we’ve noticed a significant improvement in overall business efficiency.

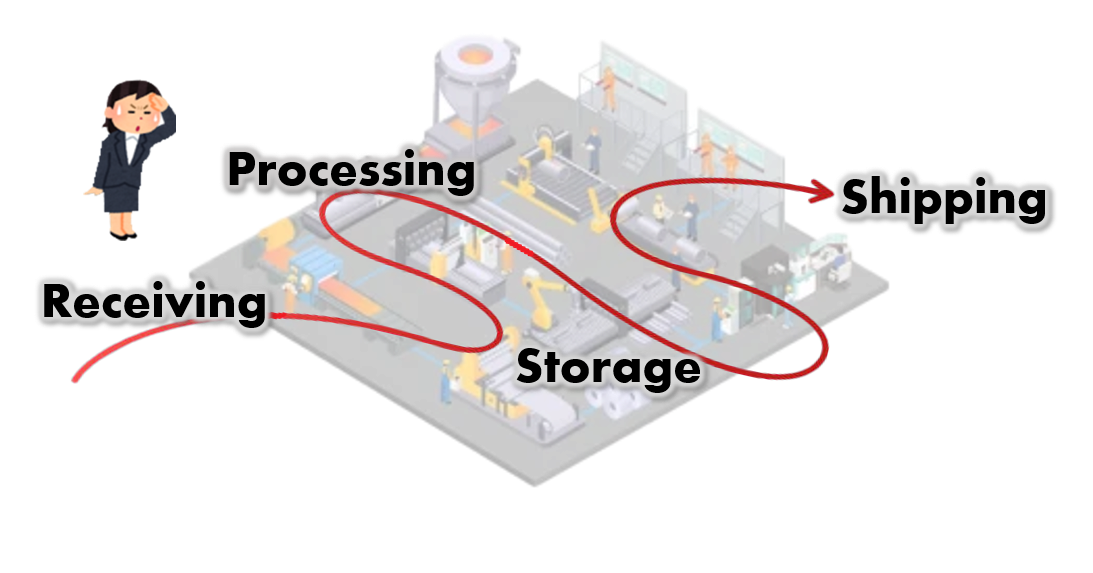

However, we still face challenges in transforming our factory into a smart factory that meets global standards.

/Challenges

- Lack of accurate communication during design and production changes.

- Insufficient tracking of production order progress.

- Poor monitoring of work-in-progress inventory

- Incomplete collection of quality data

/Negative Impacts

- Delays in delivery

- Quality issues

- Inefficient use of resources

- Inventory imbalances

- Cost increase

- Customer dissatisfaction

“DELMIA Apriso” is the right answer to solve the following challenges and enhance to global industry standard.

- Operation management across divisions and plants.

- Rising of costs but reduced of budget

- Traceability to meet competitive and requirement

- Maintain the product quality level

How does “DELMIA Apriso” address those challenges?

“DELMIA Apriso” is a solution dedicated to Manufacturing Operations Management (MOM).

- Optimizing production lines, improving quality control, and managing real-time data through its Manufacturing Execution System (MES)

- Seamlessly integrate with Enterprise Resource Planning (ERP) systems to ensure seamless communication and data exchange between manufacturing operations and other business functions.

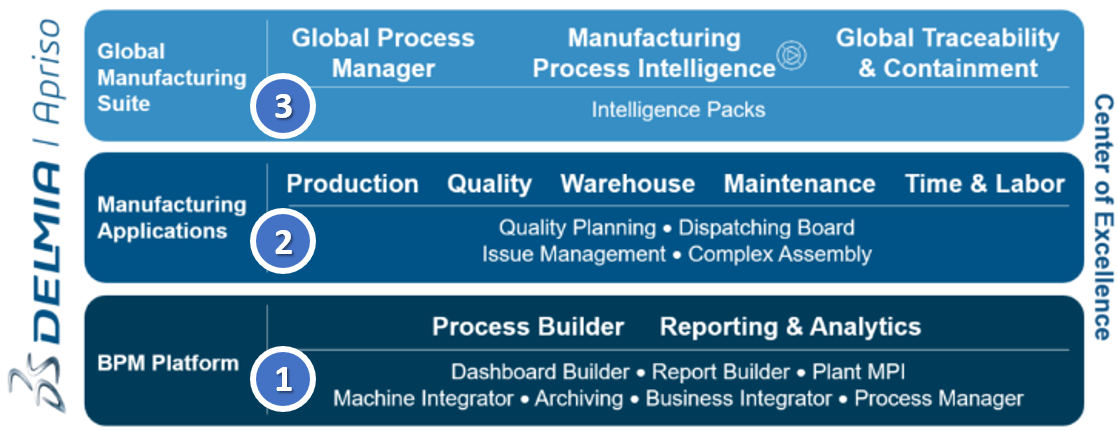

“DELMIA Apriso” integrated with three key components.

① BPM (Business process modeling) platform

- A tool designed to streamline, control, and optimize business processes in manufacturing environments.

[Features]

- Process Visibility and Optimization > move to No.3

- Manufacturing process management (work instruction, database object and etc…)

- Standardization and automation of business process

- Planning equipment maintenance

② Manufacturing applications

- A tool designed to manage and optimize manufacturing operations

[Features]

- Real-Time Monitoring and Control

- Production Scheduling and Optimization

- Quality Management

- Inventory Management

③ Global manufacturing suite

- A tool designed to (optimize > support) and manage manufacturing operations on a global scale.

[Features]

- Manufacturing Operations Management

- Flexible Production Scheduling > Control and track process, products, materials

- Quality and Compliance Management

- Supply Chain and Inventory Management

- Data-Driven Analytics and Process Improvement

- Sustainable Manufacturing

- Real time process Visibility and Optimization

Can you tell me more details about how those manufacturing applications helps address our challenges?

Sure!

Here, let me just give you two examples of ②Manufacturing Applications: “Production” and “Quality”.

ex1) ②Manufacturing Application – “Production”

[Features]

- Synchronize material flows with manufacturing by tracking and visibility of material

- Supports paperless by detailed digitalized and 3D work instructions

- Configurable work instructions and full revision control

[Benefits]

- Reduce cost of goods sold

- Increase manufacturing efficiency

- Facilitate manufacturing flexibility

ex2) ②Manufacturing Application – “Quality“

[Features]

- Tracks and analyzes quality and defects across operation

- Security control, audit trails, electronic and double signatures

- Provide a visual way to capture and analyze quality defect on the shop floor

[Benefits]

- Improve cost efficiency in quality management

- Reduces the cost of regulatory compliance

- Supports APQP/TS16494

I understand it.

Thank you very much!

“DELMIA Apriso” helps..

- Accelerate time-to-market

- Improve cost/intentory management

- Maintain quality

- Ensure compliance with international standards across global manufacturing operations