Virtual Server, Virtual Desktop

Server, Workstation, PC, Peripherals

Windows, Unix, Oracle, SQL

Netapp, Buffalo

Network System Design & Construction

Fundamentals Course, Advance Course, Custmized Course

3DEXPERIENCE Entrance

Order Custom-made Training for specific applications. CADmeister, FTI, XVL, CADdoctor etc..

Annual Maintenance Support

CAD/CAM/CAE/PLM Consultation & Implementation

CAD/CAM/CAE/PLM System Operation Support

IT System Administration Support

CADmeister is a professional application tool that can reduce costs and save time, and provides the best solution for MOLD/PRESS Die companies. CADmeister provides dedicated functions covering from product design to Die design and Die production, which greatly shortens the product development process and enables each function to be automated and rationalized.

Improve your work efficiency. Stabilize your work quality.

Stabilize your work quality.

The different levels of engineers deliver the same quality of products.

All-in-one system with advanced functions covering everything from Design to Planning and Production for PRESS/MOLD Die manufactures.

Packages

CAD (Base configuration)

A hybrid modeler capable of operating wire frame models, surface models, and solid models, performs set operations of mixed data of surface model and solid model, and enables modeling environments that are freed from the restrictions due to the differences in the types of data models.

MOLD DIE (Support for designing of molds)

Supports each phase of structuring a mold: initial design consideration, considerations of cavity and core, conceptual design, detailed design, creation of drawing, preparation of data for order placement.

PRESS DIE (Support for designing press dies)

Supports designing press dies. It consists of three key function items: design support, modeling support, and post-process support.

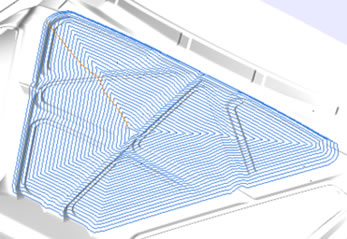

CAM (3D CAM System)

Supports machining data creation for both solid and surface models.

PRESS Options

(Support for creating Blank Deployment Lines and Flange Deployment Lines.)

A simple simulation tool that helps shaping a press die. Quick creation of ‘Blank Deployment Lines’ and ‘Flange Development Lines (Trim Development Lines)’ for cost estimation at the initial stage of design. Viewing increase/decrease in metal thickness and analyzing cracks and wrinkles for quick detection of poor shapes

(Support for modeling and forming)

Perform the characteristic patterns of press die forming, confirm the accuracy of anticipated deformation amounts, confirm an empty-weight deflection, and model by considering the anticipated deformation amounts, the characteristics of materials and STL figures.

_CADmeister.jpg)

_CADmeister.jpg)

(Support for stress analysis)

A simulation for Designers. Perform a stress analysis through seamless operations of CAD and CAE.

(Support for forming molds)

Support for creating Blank Deployment Lines and Flange Deployment Lines.

(Analytical tool for resin mold designers)

Supports designers by reducing design lead time and improving mold qualities, due to the capabilities of mold cooling analysis and mold deflection analysis.

Feel free to contact us for products and solutions.

Contact