Virtual Server, Virtual Desktop

Server, Workstation, PC, Peripherals

Windows, Unix, Oracle, SQL

Netapp, Buffalo

Network System Design & Construction

Fundamentals Course, Advance Course, Custmized Course

3DEXPERIENCE Entrance

Order Custom-made Training for specific applications. CADmeister, FTI, XVL, CADdoctor etc..

Annual Maintenance Support

CAD/CAM/CAE/PLM Consultation & Implementation

CAD/CAM/CAE/PLM System Operation Support

IT System Administration Support

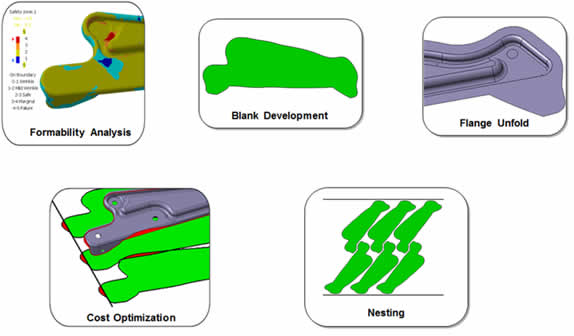

Forming Technologies (FTI®) is the world's leading provider of software solutions for the design, feasibility, and costing of sheet metal components.FTI has provided OEMs and suppliers in the automotive, aerospace, electronics, and appliance industries with innovative solutions designed to reduce development time and material costs.

To calculate and reduce material cost in the early stage of product design brings a dramatic cost reduction in the end.

Reduce material cost, Quick cost estimation

Identifies product design changes that improve material utilization and reduce costs.

Accurately determines total material cost per blank.

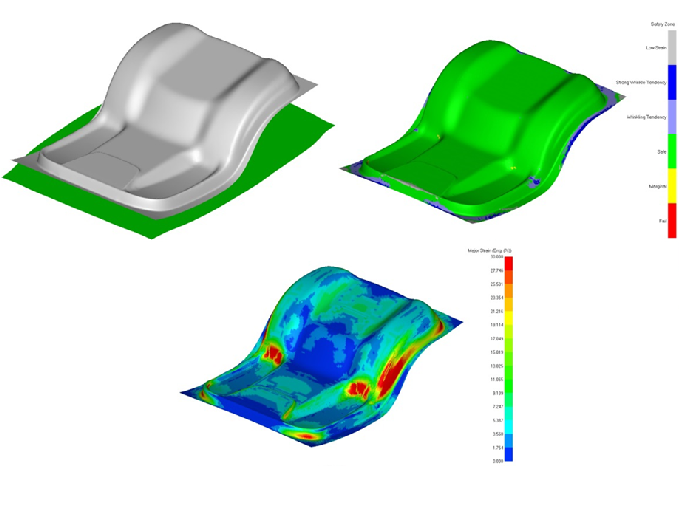

Accurately identifies material thinning and gathering conditions.

Evaluates multiple costing scenarios for optimal material utilization.

Specifically designed for purchasers, planners, estimators, engineers, account managers, and tool and die designers.

Improve product design

Enable users to implement changes earlier in the product life cycle.

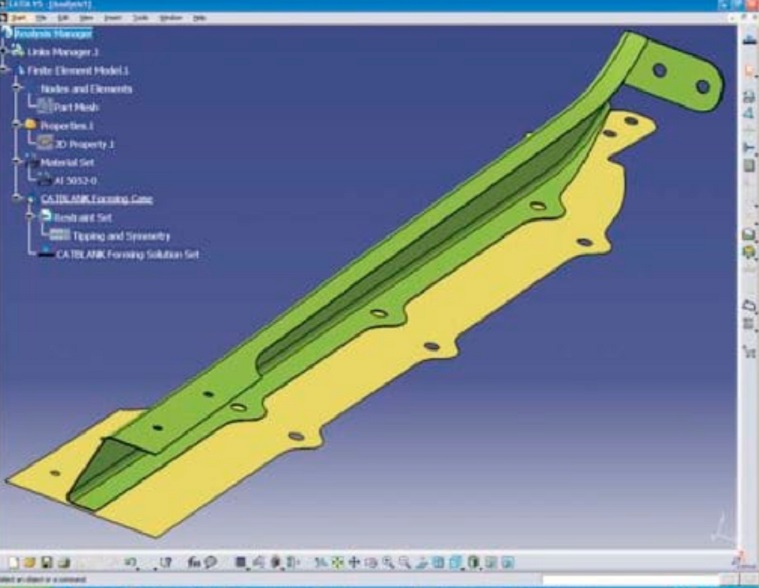

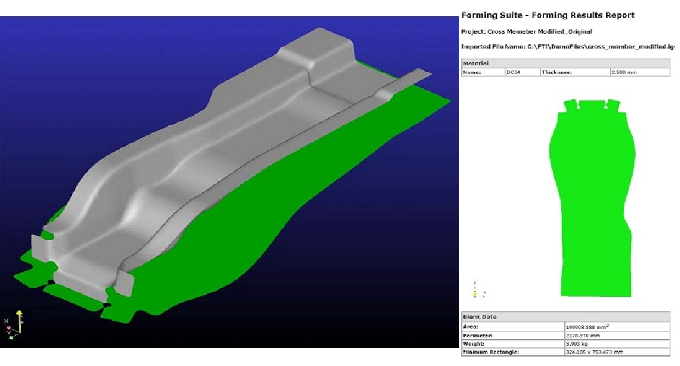

Formability results consider component or tool geometry and account for material properties, friction, binder surface, die addendum, blank holder force, pad pressure, draw beads, and tailor-welded blanks.

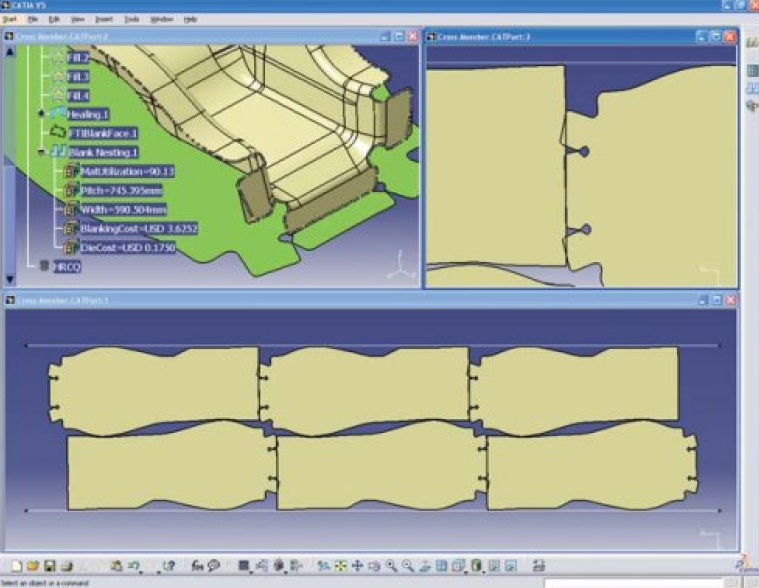

Covers the entire process from quoting to process design to virtual prove-out with speed and efficiency by powerful stamping analysis tool for blank development, process design, and incremental simulation.

Reduce material cost

Reduce time for cost estimation

Reduce parts weight

Reduce time for negotiation with suppliers

Reduce rework by improving product design with formability

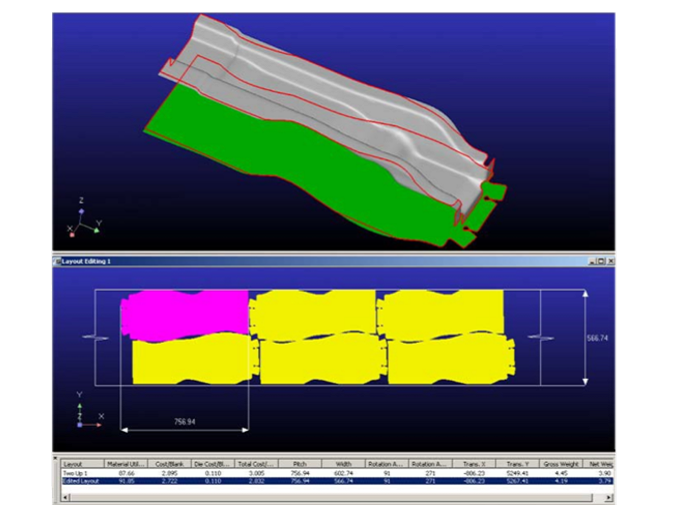

Support a fast and accurate method for developing blank shapes and coil nests, and makes recommendations to modify stamped component designs for cost reduction.

Designed to reduce material costs and limit expensive engineering changes.

Find out parts in product to be modified to improve yield rate

Improve product design predicting forming problems such as cracking, wrinking

Support a fast and easy blank shapes creation.

Calculates initial blank shapes for die design and cost estimating in minutes.

Quickly Create Blank

Reduces material costs and number of trials in the prove out stage

Generates a report in excel and HTML format

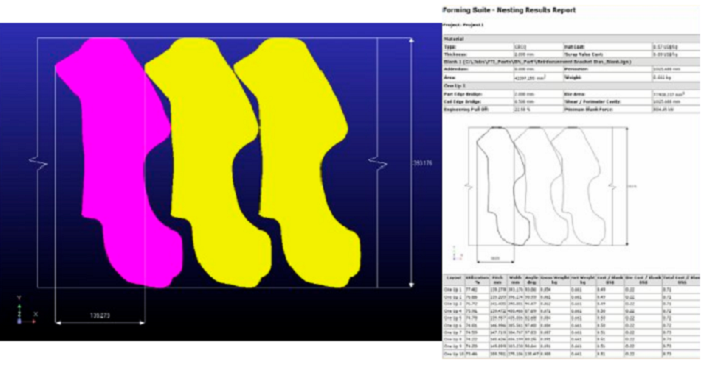

Determines optimal material usage thru geometric nesting of blanks in minutes.

Accurately determines total cost per blank.

Evaluate multiple nesting scenarios quickly

Generates a report in excel and HTML format

Feel free to contact us for products and solutions.

Contact